Popular keywords: Blister machine Cup making machine Packer High frequency Punch

搜索

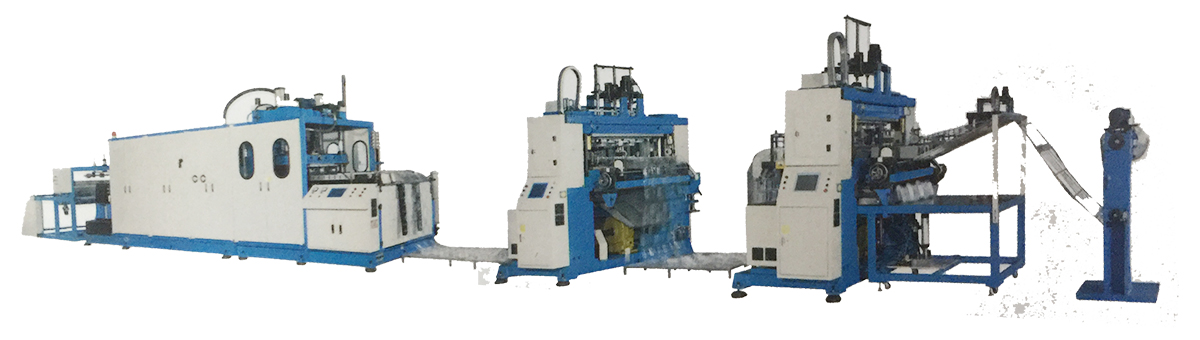

HX-1000 Air pressure and Vacuum Forming Thermoforming Machine - Four station

| Model / parameter | HX-1000 |

| Adapt to material | PP, HIPS, OPS, PET, PVC, PE, ABS, PSP |

| Vacuum forming area (mm) | W1000 * L1200 |

| Pressure forming area (mm) | W800 * L810 |

| Forming depth (mm) | max.150 |

| Forming speed (cycles / min) | 4-15 |

| Sheet width (mm) | 640-1040 |

| Sheet thickness (mm) | 0.1-1.8 |

| Forming power (kw) | 15 |

| Feeding horsepower (kw) | 15 |

| Clamping force (T) | 40 |

| Electric furnace specifications (kw) | Up and down double furnace type 195KW |

| Electric furnace control | 83 groups temperature control switch + PLC |

| Operation method | PLC + can store 300 groups of settings |

| Mechanical size (mm) | L7100 * W2150 * H3050 |

| Mechanical weight (kg) | About 13000 |

product description

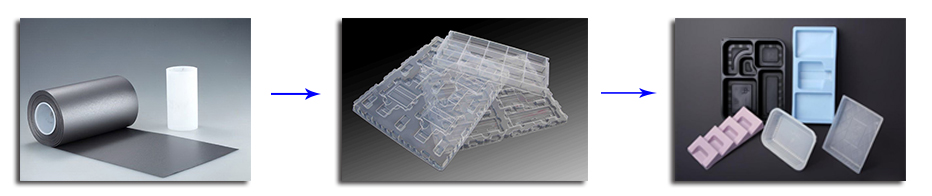

It is a plastic forming equipment that collects and sends tablets, heating, forming, punching, punching, stacking, recycling of waste coils, and crushing at one time. Only one person is required to pack into the box, and the product is safe and sanitary without secondary pollution.

Feature description

01. Patent clamping device, automatic adjustment

02. Chain base width buffer design, no card chain caused by insufficient heating of the sheet

03. The heating adopts upper and lower ceramic heating plates, SSR, calculus PID temperature control

04. Nodular cast iron is used for the forming seat, which can better exert the high pressure of clamping.

05. Suitable for real and compressed products, PP, HIPS, OPS, PET, PVC, PE, ABS, PSP ... and other food and industrial packaging.

06. PLC humanized operation, quick mold change, 300 modules can be memorized

Punching part

| Cutting size (mm) | W1050 * L1350 |

| Cutting height (mm) | max.150 |

| Cutting stroke (mm) | 220 |

| Cutting speed (times / minute) | 30-75 |

| Cutting pressure (T) | 5 |

| Motor power (kw) | 7.5 |

| Film removing device | 2kw servo motor |

| Feeding device | 1kw servo motor |

| Mechanical size (mm) | L2750 * W2240 * H2980 |

| Mechanical weight (kg) | About 5000 |

01. Cooperating with the forming machine for punching and counting collection

02. Servo control is accurate and fast

03. The eccentric shifts on a straight line and moves with high torque and low noise

04. Two-stage feeding for convenient control of modulus and times

05. Fast mold change, easy operation with PLC & humanized touch screen

06. Suitable for cutting PP, HIPS, OPS, PET, PVC, PE, ABS, PSP, etc.

07. Equipped with a waste collection rack, automatic recovery of material pieces, convenient for labor saving

08. Equipped with crushing and recycling machine, waste recycling and crushing, saving manpower space and time

Leave message

Product classification

Contact us

Address: low mountain, new industrial zone north of Shenzhen city of Guangdong Province, No. 12

Address: Hongkong Hongkong No. 7 Street Kwun Tong Kowloon into the industry center of Ningjin 29 building B5-3

Address: Taiwan province Taiwan Beitun district water in Taichung city waterscape Lane 22 Lane 803

Tel:0755-28942718/728

Fax:0755-28942708

Tel:+86-135-4332-8952

Mail:sales1@szhx-tw.com

Web:https://www.szhx-tw.com

domestic:https://huaxiangjx.1688.com/

overseas:https://hxauto.en.alibaba.com/

WeChat public

Copyright © 2019 Shenzhen Longgang city Longgang District Huaxiang Machinery Factory 粤ICP备11060815号 300.cn

online service

online service