Popular keywords: Blister machine Cup making machine Packer High frequency Punch

High frequency mode

product description:

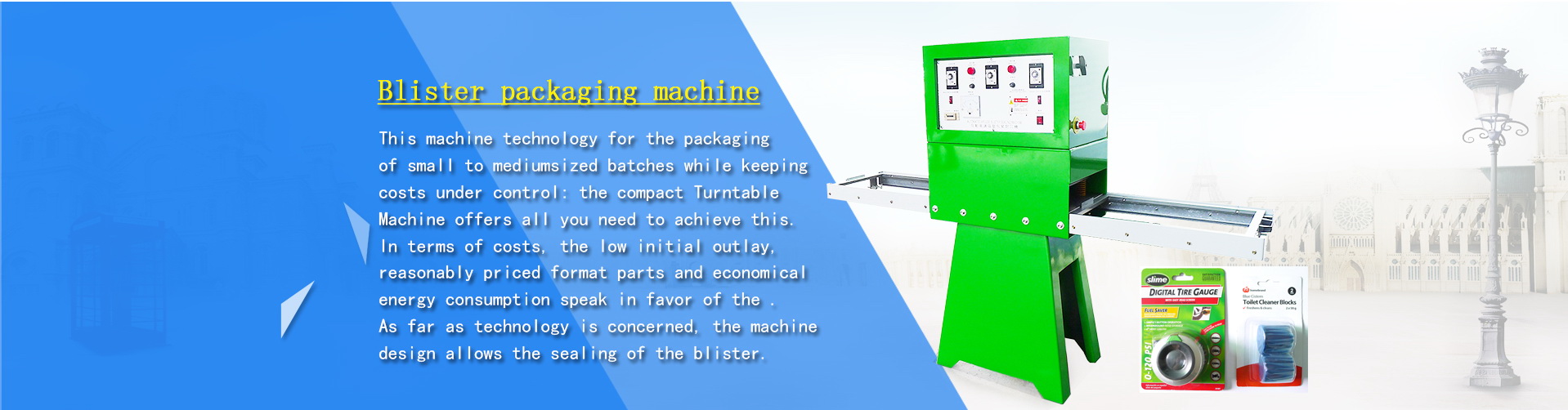

The high-frequency electromagnetic field is used to polarize the molecular structure of the processed material under the action of the high-frequency electric field, and then pressure is applied to achieve the complete welding equipment. High frequency mold is applied to high frequency plastic welding machine. High frequency plastic welding machine (also called high frequency heat sealing machine) is mainly used for a series of tasks such as heat sealing, voltage, welding, sealing, trimming of PVC or materials containing more than 20% PVC, and can also be used for environmental protection such as PET, GAG Blister seal of material. Specific products are: single / double-sided blister packaging

Mold characteristics:

1. The function of high frequency mold: the shape of the sunshade and mirror cover is fused (fuse). Frame, plane, door panel embossing.

2. Properties of high frequency mode: unbreakable after fusion. After fusing, the burrs should not be too long. There is no phenomenon of extruding in the fusion part.

3. The design focus of high frequency mode: Closed mode height setting.

The upper and lower phantom fused gaps are set.

Setting the inclination of the knife edge of the upper mold body.

4. The evolution of high-frequency molds: copper mold fuse steel mold two-stage (spring-type)

Required equipment:

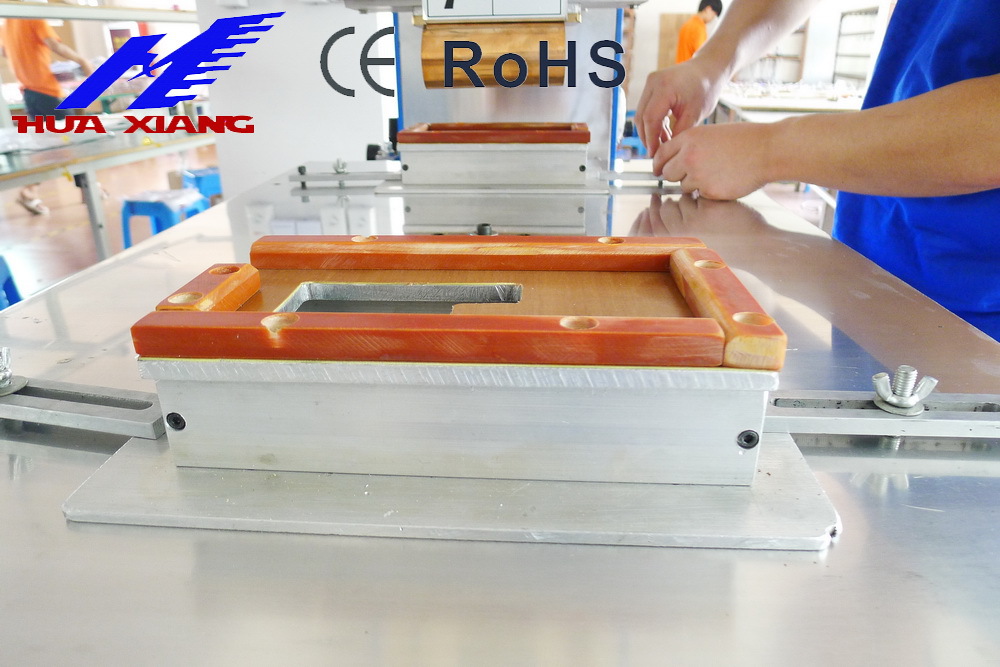

High frequency mold is applied to high frequency plastic welding machine; the picture shows the mold installation

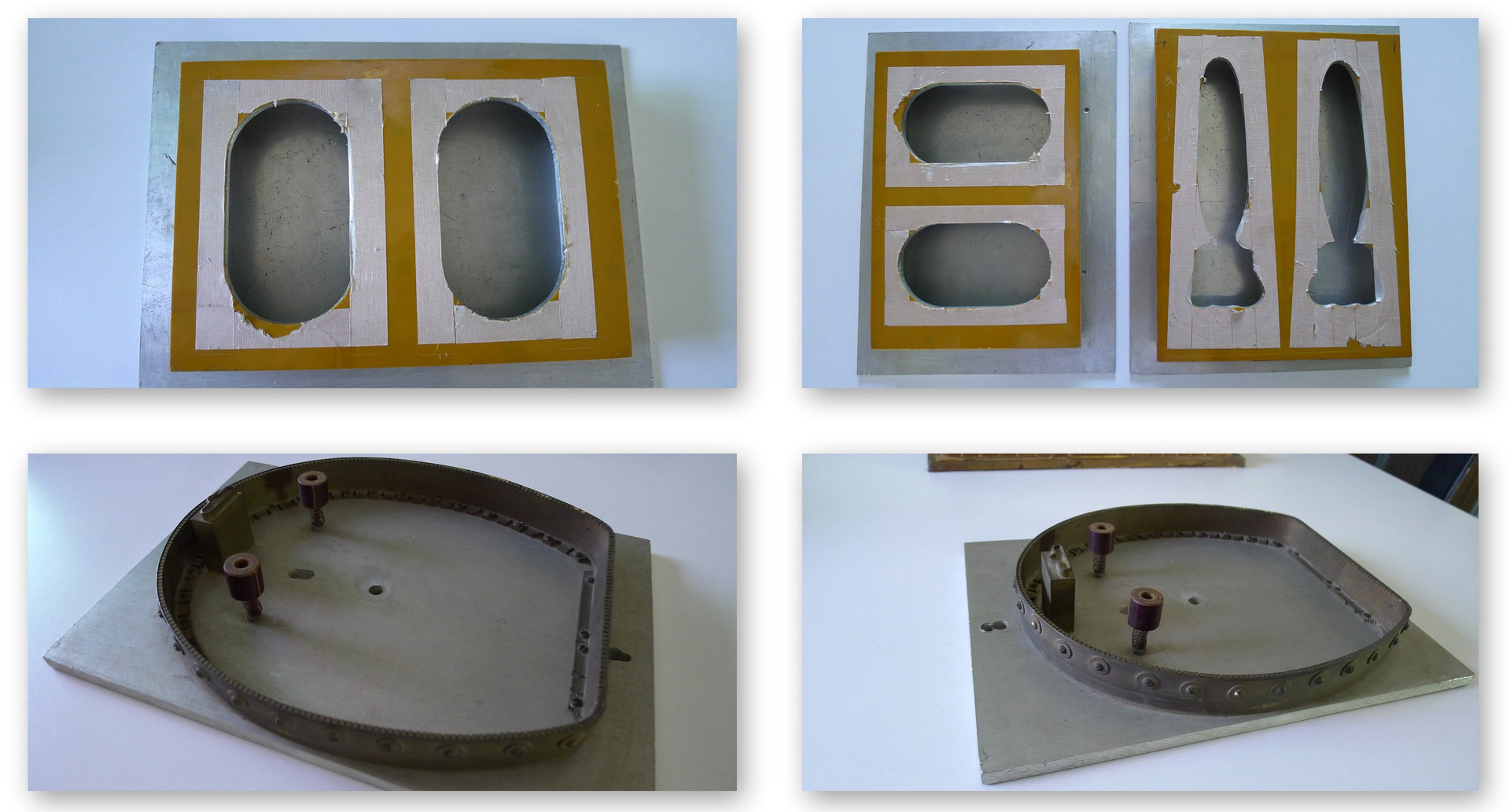

Product needs, high frequency mold can be divided into upper and lower mold

Click the link to learn more: https://detail.1688.com/offer/529377906207.html?spm=a2615.7691456.0.0.917aca87W8ahf

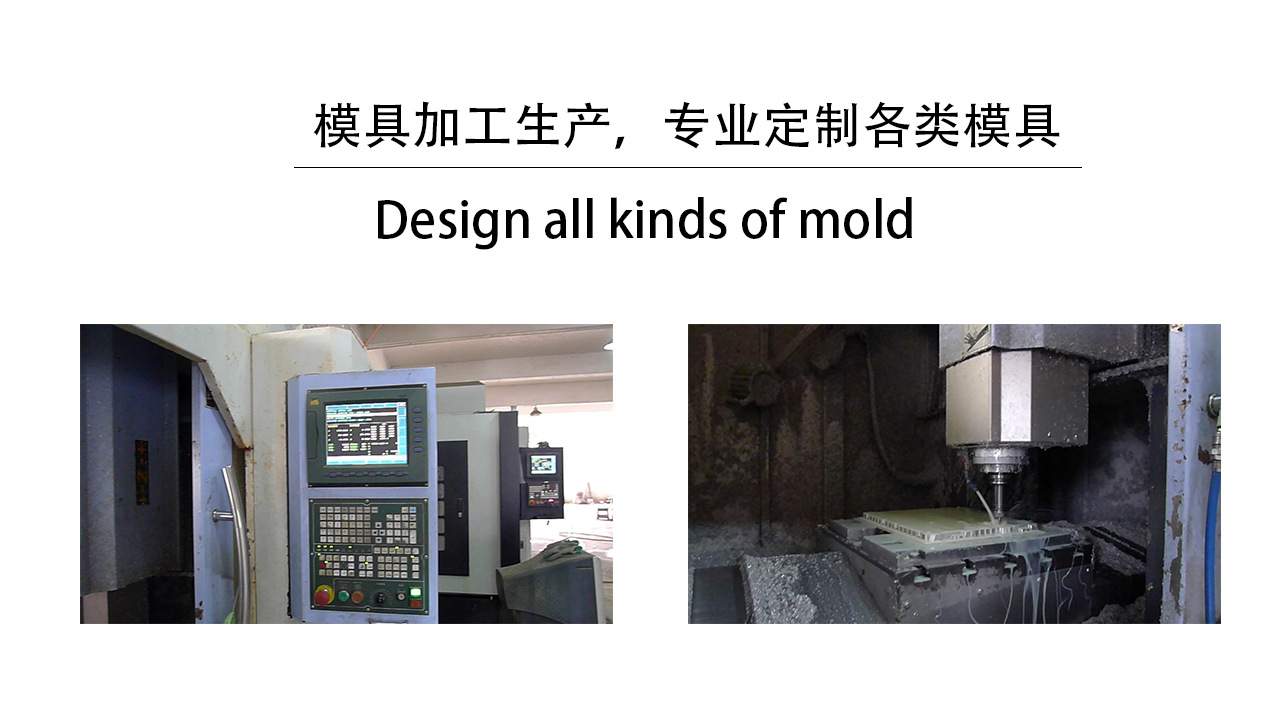

Design process of high frequency mold:

1. Drawing confirmation: production set provides 2D or 3D finished product drawings-drawing size confirmation-drawing mold assembly drawing-setting closed mold height drawing drawing of each single piece of mold-drawing (CAM program conversion)

2. Material specifications required for purchase according to the mold drawing. Make the required size and shape according to the drawing.

3. Both sides of the size and shape produced by processing are parallel. (The height of the copper sheet is all equal, and the parallelism tolerance must be within + -0.05-).

4. Make the door panel holder (the holder is the size given in the drawing).

5. Paste the finished product image on the aluminum plate, and then fix all the copper pieces on the aluminum plate with a holder according to the shape of the drawing.

6. Fix the anchor A on the aluminum plate as the size of the door panel.

7. Make the holder with foam on the top and its height is about 3-5mm lower than the copper mold surface.

8. Make a handle on each side of the left and right to fix it on the aluminum plate to facilitate transportation.

9. Confirm that the dimensions of each part of the mold are correct.

10 test mold (current, pressure, screen current will vary depending on the size of the mold).

Products real shot:

Company Profile:

Shenzhen Huaxiang Automation Machinery Equipment Co., Ltd. was established in Shenzhen, the earliest development of China's plastics industry. It is an industrial and trade integrated enterprise integrating R & D and production. The company occupies an area of 2,000 square meters. Taiwan's industrial technology can provide a series of packaging machinery and solutions for the entire production line, including mold customization, material supply, and finished product foundry. Customers throughout the country, exported to India, Vietnam, Myanmar, Thailand, Taiwan and so on.

Contact information:

Address: Longgang District new village 12 D Low Hill Road, Building

Website: www.szhx-tw.com

-mail: hx@szhx-tw.com

QQ: 800 026 708

Tel: 0755-28942718

Mobile: 13903021604 (Rao Health)

Mobile: 18925218992 (Ms. Rong)

Product classification

Contact us

Address: low mountain, new industrial zone north of Shenzhen city of Guangdong Province, No. 12

Address: Hongkong Hongkong No. 7 Street Kwun Tong Kowloon into the industry center of Ningjin 29 building B5-3

Address: Taiwan province Taiwan Beitun district water in Taichung city waterscape Lane 22 Lane 803

Tel:0755-28942718/728

Fax:0755-28942708

Tel:+86-135-4332-8952

Mail:sales1@szhx-tw.com

Web:https://www.szhx-tw.com

domestic:https://huaxiangjx.1688.com/

overseas:https://hxauto.en.alibaba.com/

WeChat public

Copyright © 2019 Shenzhen Longgang city Longgang District Huaxiang Machinery Factory 粤ICP备11060815号 300.cn

online service

online service