Popular keywords: Blister machine Cup making machine Packer High frequency Punch

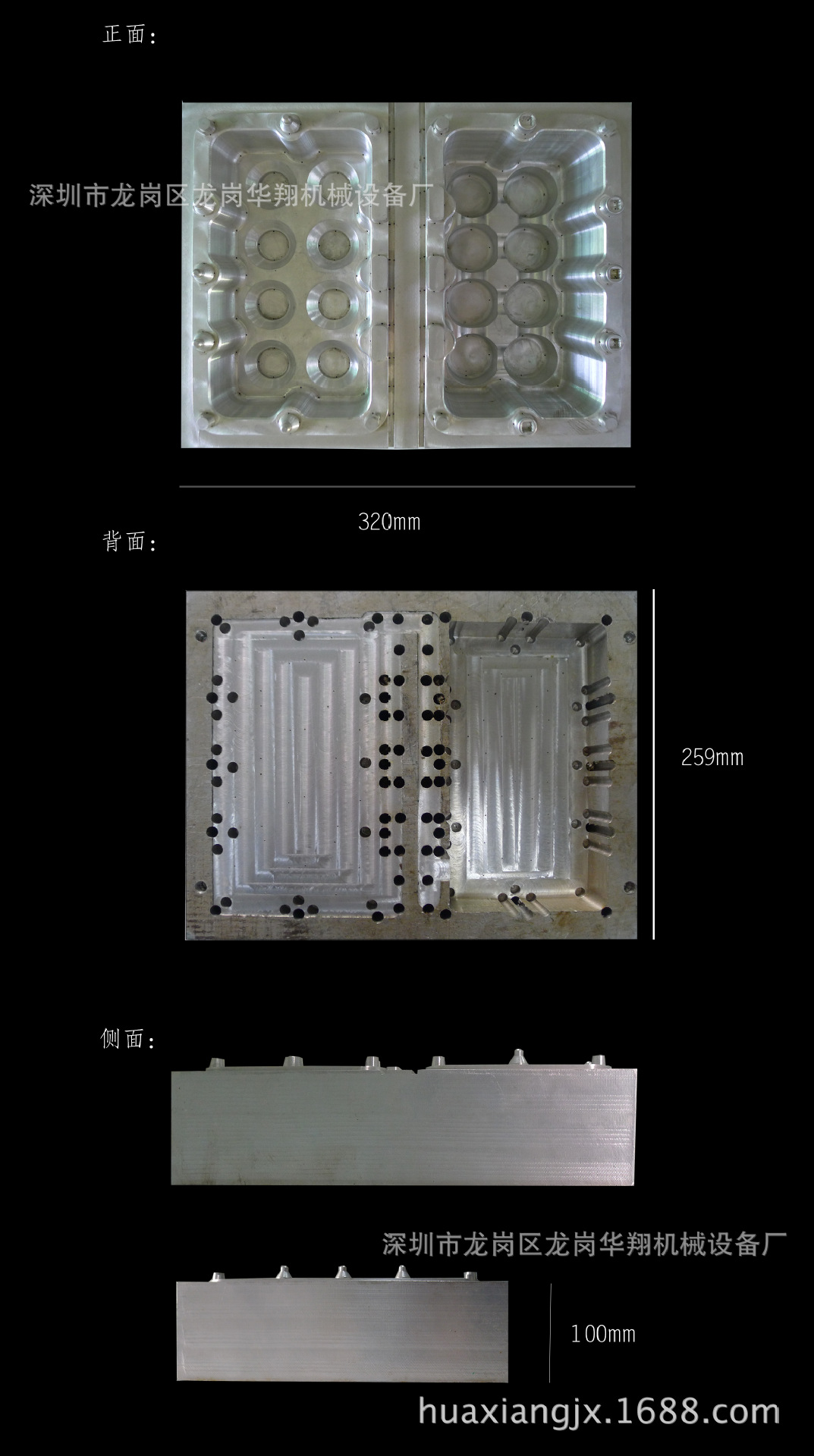

Aluminum mold

product description:

Plastic mold refers to the mold used in the production of plastic. The lowest cost is the plaster mold, followed by the electroplated copper mold and the resin mold, and the most expensive is the aluminum mold. A small hole is drilled in the mold, which is used to vacuum adsorb the heated hard film to form a blister product.

Gypsum molds are suitable for proofing and small batch production; copper molds are metal molds that are more durable. The appearance and transparency of products produced by such molds are better; mold making prices are lower; resin molds are more expensive than copper molds and plaster tools, but The use degree is equivalent to that of copper mold, and it is more durable. It can solve some technical problems that copper mold and gypsum mold cannot handle, such as water marks on the wall of the product ; aluminum mold has high accuracy and the profile and angle of the product are beautiful and durable. The degree is very high, and the price is also the first of the four types of molds.

Alloy aluminum mold:

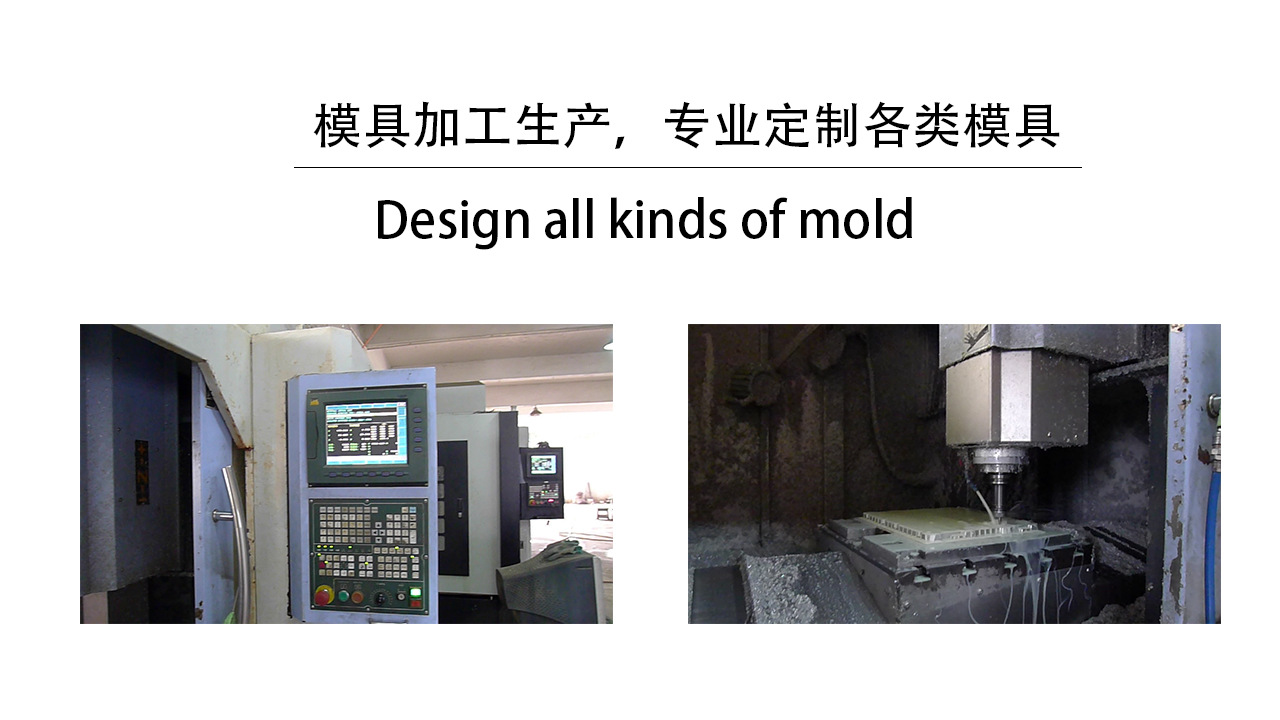

According to the provided drawings or templates, a program is issued through programming software such as CAM, which is processed by a CNC machine tool, and then other manual production such as blowholes and undercut positions is completed, and the mold can be polished and smoothed. For special requirements, spray Teflon or sandblast. Made of aluminum materials such as ZL401, 6061, and 7075, this type of mold has high accuracy and the profile and angle of the product are beautiful, and the durability is very high. The price is also the first of the four types of molds; it is mainly suitable for electronics , Gifts, toys, medicine, stationery, and other products with high appearance and size requirements; in fact, aluminum alloy molds are a large number

Click the link to learn more: https://detail.1688.com/offer/529600711773.html?spm=a2615.7691456.0.0.917aca8ntdjnz

Company Profile:

Shenzhen Huaxiang Automation Machinery Equipment Co., Ltd. was established in Shenzhen, the earliest development of China's plastics industry. It is an industrial and trade integrated enterprise integrating R & D and production. The company occupies an area of 2,000 square meters. Taiwan's industrial technology can provide a series of packaging machinery and solutions for the entire production line, including mold customization, material supply, and finished product foundry. Customers throughout the country, exported to India, Vietnam, Myanmar, Thailand, Taiwan and so on. !!

Contact information:

Address: Building D, No. 12, North Low Shan Road, Xinsheng Village, Longgang District, Shenzhen

Website: www.szhx-tw.com

Email: hx@szhx-tw.com

QQ: 800026708

Phone: 0755-28942718

Mobile: 13903021604 (Rao Sheng)

Mobile: 18925218992 (Ms. Rong)

mold renderings:

Mold real shot:

Product classification

Contact us

Address: low mountain, new industrial zone north of Shenzhen city of Guangdong Province, No. 12

Address: Hongkong Hongkong No. 7 Street Kwun Tong Kowloon into the industry center of Ningjin 29 building B5-3

Address: Taiwan province Taiwan Beitun district water in Taichung city waterscape Lane 22 Lane 803

Tel:0755-28942718/728

Fax:0755-28942708

Tel:+86-135-4332-8952

Mail:sales1@szhx-tw.com

Web:https://www.szhx-tw.com

domestic:https://huaxiangjx.1688.com/

overseas:https://hxauto.en.alibaba.com/

WeChat public

Copyright © 2019 Shenzhen Longgang city Longgang District Huaxiang Machinery Factory 粤ICP备11060815号 300.cn

online service

online service